LESSON

– WOOD BASICS

LUMBER

Lumber is a generic term that applies to various lengths of wood used as

construction materials. Pieces of lumber are cut lengthwise from the trunks of

trees and are characterized by having generally rectangular or square cross

sections. (Source)

WOOD GRAIN

Grain is the term used to describe the alternating dark and light regions

found in wood. The grain patterns are a

result of the growth of the wood. Different

types of wood result in different looking grains.

When we refer to the direction of the wood grain, we are in fact

referring to the orientation of the wood’s fibers.

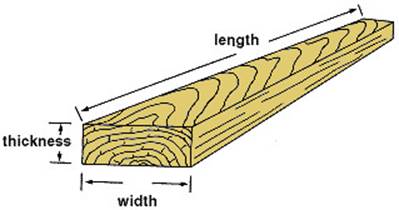

DIMENSIONS

A board of wood has three dimensions: length, width and thickness. Each is shown in the image below.

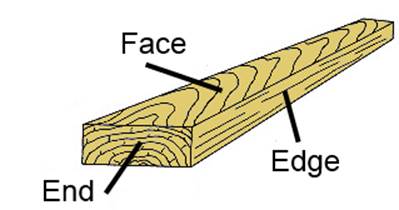

SURFACES

There

are three types of surfaces on a board: face, edge and end. Of course, each board has two of each type of

surface.

MEASUREMENT UNITS

In Canada, we are accustomed to working with the metric system. In this system, the most common measurement

units are:

|

|

|

Amount of mm |

|

Millimeters |

mm |

1 |

|

Centimeters |

cm |

10 |

|

Meters |

m |

1 000 |

|

Kilometers |

km |

1 000 000 |

However, when working with wood and in construction, we are often forced

to use the United States’ system – the imperial system. The reason that we are forced to use the US’

system is that we import and export many construction materials from/to the US.

In the imperial system, the most common measurement units are:

|

|

|

Amount of inches |

|

Inches |

in or " |

1 |

|

Feet |

ft or ' |

12 |

|

Yards |

Yd |

36 |

|

Miles |

Mi |

63 360 |

As you can see, the metric system allows for easy conversions from one

unit to another. Conversions in the

imperial system are a little more difficult.

BOARD FOOT

When purchasing a board of wood, one sometimes encounters the term board

foot. Some believe this is a unit of

measure of distance. However, it is in

fact a unit of measure of volume. It is

equal to:

1 ft by 1 ft by 1 in

or

144 in3

NOMINAL VS ACTUAL DIMENSIONS

If you have ever purchased a 2 by 4 at the store and tried to measure its

thickness and width, you surely discovered that they are not 2 inches by 4

inches. The same is true for other sizes

of construction lumber. This is because

the board is initially cut to 2 inches and 4 inches at the sawmill. However, it is then dried and loses about 10%

of its volume. It is then planed to a

set size. A 2 x 4 is about 1.5 inches by

3.5 inches.

The nominal dimensions are 2 by 4.

The actual dimensions are 1.5 inches by 3.5 inches.

CLASSIFICATION

Lumber can be classified in three groups based on its nominal dimensions:

1. Board – Less than 2 in thick and more than 1 in

wide. Some consider boards that are less

than 6 in wide to be strips.

2. Dimension – Between 2 and 5 in thick and 2 or more in wide. Also classified as framing, joists, studs,

small timber …

3. Timber – Smallest dimension is 5 (or more) in. Also classified as beams, stringers, posts…

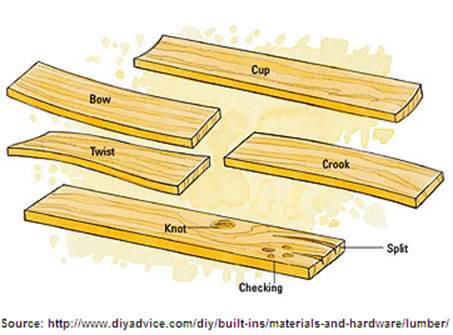

WOOD DEFECTS/IMPERFECTIONS

When choosing a piece of wood to work with, you have to be aware of imperfections

or defects. When drying, wood sometimes

curves or twists in one or more directions.

Each one has it’s specific term: cup, bow, crook and twist.

These curvatures have to be considered because they will cause greater

waste when you are reducing your board to the desired dimensions. In fact, you might not have enough wood left

to create the desired piece.

Knots, splits and checking are

imperfections that you want to avoid.

Some people (like Mr. Campeau) do enjoy the look of knots. However, one has to be careful that the knot

is not (no pun intended) loose or the piece could end up with a hole in it! Cutting through a knot can also lead to poor

cuts and breaking of edges.

TYPES OF WOOD

There are many types of wood that are used. One can classify types of wood into two

branches: softwood and hardwood. As the names suggest, softwoods are usually

softer than hardwoods. However, this is

not always the case. For example, balsa

wood is a hardwood and one of the softest woods.

Softwoods are generally evergreens while hardwoods are deciduous

trees. According to Wikipedia, about 80%

of the entire world’s produced lumber is softwood.

Softwood trees grow faster than hardwood trees and are therefore more

renewable. Softwood trees also tend to

have long straight sections which are friendlier to lumber production. These characteristics of softwoods lead to

them being less expensive than hardwoods.

SPECIES

There are many species of woods.

In Canada, evergreen species include pine, cedar, larch, fir and

spruce. In fact, these are really

families of species with several types in each.

Canadian deciduous trees include different types of ash, birch, oak,

maple, poplar and elm.

Click here to see a small list of species of

wood and characteristics and uses for that species. Note that this is not by any means a complete

list.